Forged Grinding Ball

Forged grinding balls are widely used in powder preparation and ultra-fine deep processing in cement building materials, metal mines, coal slurry thermal power, chemical engineering, ceramic coatings, light industrial papermaking, magnetic materials and other industries. The product has high hardness, low wear, good

Why choose us?

Premium Quality

Manufactured with advanced technology and strict quality control for consistent performance.

Tailored Solutions

Available in different grades, specifications, and finishes to meet diverse industry needs.

Sustainable Choice

Eco-friendly processes and recyclable materials to support sustainable manufacturing.

Global Standards

Compliant with international certifications, ensuring reliability and customer trust worldwide.

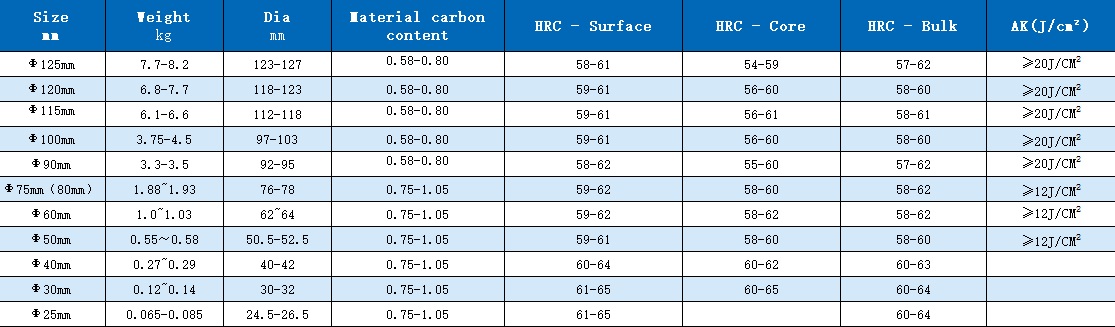

Product Specification

Strict Quality Control System

Forged grinding balls are industrial steel balls produced through a specific rolling process. They possess precise dimensions, high hardness, strong wear resistance, and resistance to deformation, and are mainly used in grinding operations in mines, power plants, cement plants, and other fields.

The production process follows the YB/T 091-2005 industry standard. Using round steel bars as raw material, the balls are continuously formed by heating and rolling with spiral die rolls. An online quenching and tempering process is then used to enhance hardness. Quality is controlled using high-quality carbon steel and alloy steel materials to ensure uniform hardness and a low breakage rate in the finished product. The steel balls maintain stable shape throughout the processing, with no loss of roundness.