High Chrome Grinding Balls

Chromium alloyed cast grinding balls are widely used in powder preparation and ultra-fine deep processing in cement building materials, metal mines, coal slurry thermal power, chemical engineering, ceramic coatings, light industrial papermaking, magnetic materials and other industries. The product has high hardness, low wear, good

Why choose us?

Premium Quality

Manufactured with advanced technology and strict quality control for consistent performance.

Tailored Solutions

Available in different grades, specifications, and finishes to meet diverse industry needs.

Sustainable Choice

Eco-friendly processes and recyclable materials to support sustainable manufacturing.

Global Standards

Compliant with international certifications, ensuring reliability and customer trust worldwide.

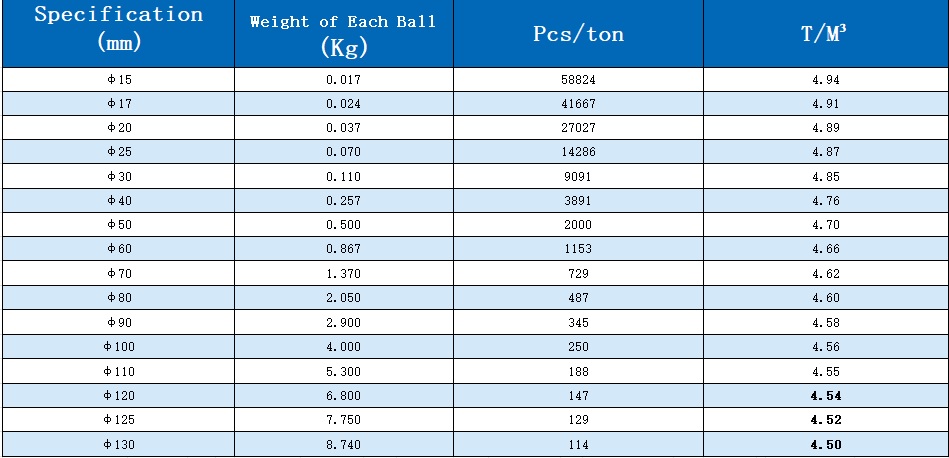

Product Specification

Specification

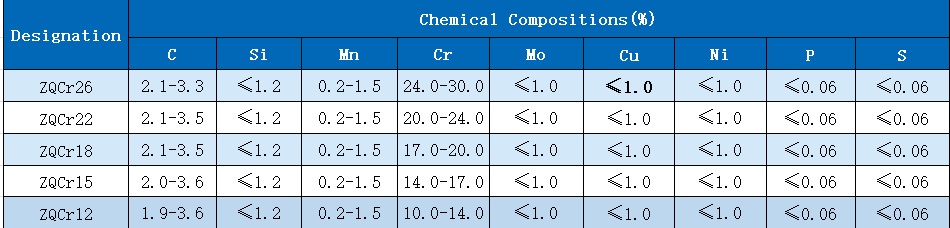

Chemical Compositions (%)

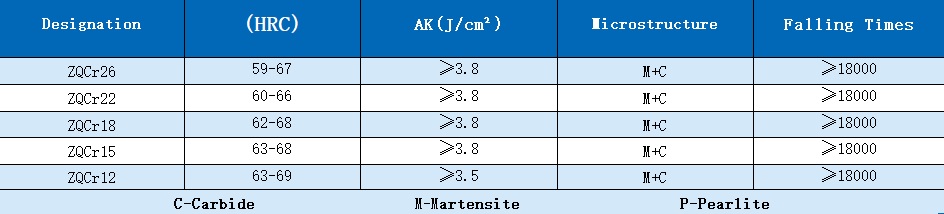

Mechanical Properties and Microstructure

Strict Quality Control System

High quality raw materials

Raw materials are an important production factor for a company, and high-quality and stable products cannot be separated from stable and high-quality raw materials. Our raw materials are supplied by stable and cooperative suppliers, and all incoming raw materials and auxiliary materials are subject to a comprehensive quality supervision mechanism. According to their specific circumstances, full inspection, random inspection, or batch inspection are carried out.

Unique chemical composition ratio

Chemical composition is one of the key factors affecting quality. Reasonable chemical composition is gradually optimized through long-term exploration. We have a unique chemical composition matching method, which enables it to better serve the combination of toughness and hardness, achieving the ideal state.

The corrosion of the grinding medium can affect its lifespan and performance. It is usually the characteristics of water or ore with acidic pH levels that create corrosive environments. The solution to this problem is to increase the chromium content in the grinding medium. Compared with low chromium grinding media, grinding media with high chromium content have a longer lifespan and can maintain shape during wear.

Precisely controlled smelting process

Adopting an acidic fast intermediate frequency induction furnace for melting and melting, precise control of temperature and composition is achieved using a far-infrared high-temperature thermometer, digital controlled heavy feeding system, and advanced spectral element analyzer; Timely deoxidation, desulfurization, and dephosphorization treatment of molten steel ensures the quality of the steel, fully utilizing the melting capacity of the intermediate frequency furnace and the processing capacity of harmful components.

Strict molding process

Track the material and composition of the sand mold during production to ensure that all parameters of the sand mold meet the requirements, and try to avoid and reduce the occurrence of insufficient pouring, sand inclusion, shrinkage, porosity, porosity, cracks, and deformation of the casting ball.

Pouring at an appropriate temperature can refine and densify the internal microstructure of the product, resulting in a radial arrangement of carbides. During grinding, this type of carbide is embedded again in the matrix, continuously forming a hard layer, thereby maintaining a reasonable intersection point between hardness and toughness, greatly improving the combination of toughness and hardness of the casting ball.

Sanfang are equipped with advanced production lines to produce wear-resistant balls and segmented products. They have the ability to automatically add sand, shape, transport, pour on line, separate sand, collect sand, and mix sand, avoiding instability caused by a large amount of manual intervention.

Mature temperature control process

The temperature control process is a very important and complex process in the production of chromium cast balls. Different discharge temperatures, pouring temperatures, mold discharge temperatures, and heat treatment temperatures are sensitively reflected in product quality. The digital temperature control steel pouring system equipped by the three parties achieves constant temperature pouring, and the appropriate pouring and discharge temperatures enable the product to reach a good state during the process from liquid to solid.

Superior heat treatment process

The superior heat treatment process enables us to fully utilize the potential of various elements. In long-term practice and exploration, we have developed a mature heat treatment process that uses a fully automatic temperature control tempering system for tempering and CNC temperature mesh belt precision quenching, which effectively releases the stress of each product and ensures a lower crushing rate of the product while ensuring hardness requirements.

Comprehensive product testing

The three parties are equipped with advanced testing equipment such as Rockwell hardness testing machine, wear testing machine, impact testing machine, metallographic microscope, drop ball testing machine, magnetic particle inspection (metal) detector, etc., which can comprehensively inspect the hardness, impact value, metallographic structure, drop ball frequency, physical defects, etc. of the product. Ensure the quality and reliability of the products used by users.