Mill & Crusher Liners

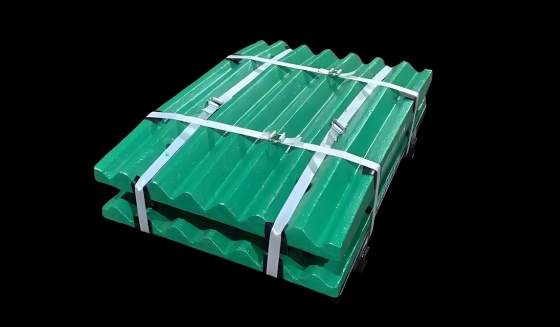

Sanfang specializes in the production of ball mill grinding liners. The unique bimetallic composite process ensures the wear resistance and toughness of grinding liners. At the same time, it also provides grinding head liners customization and improvement services.

Built to perform under the toughest conditions, our mill and crusher liners deliver superior wear resistance and consistent grinding efficiency. Manufactured using high-strength alloy steel and advanced casting technology, these liners offer precise fitment and exceptional impact absorption. Designed to extend equipment life and minimize maintenance costs, Ahsanfang’s liners provide reliable protection and optimized performance across mining, cement, and aggregate operations.

Why choose us?

Premium Quality

Manufactured with advanced technology and strict quality control for consistent performance.

Tailored Solutions

Available in different grades, specifications, and finishes to meet diverse industry needs.

Sustainable Choice

Eco-friendly processes and recyclable materials to support sustainable manufacturing.

Global Standards

Compliant with international certifications, ensuring reliability and customer trust worldwide.

Details

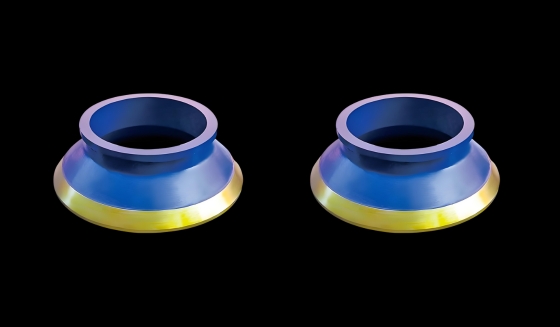

Sanfang Wear-resistant specializes in the production of grinding head liners and ball mill grinding head liners. The unique bimetallic composite process ensures the wear resistance and toughness of grinding head liners. At the same time, it also provides grinding head liners customization and improvement services.

Reasonable design of the geometry of the grinding head lining The grinding head lining is the lining installed on the inner wall of the grinding head end cover or the simplified end cover (because the flat end cover is welded on the simplified). Its main function is to protect the inner wall of the end cap from being worn by the grinding body and materials. If the design is reasonable, it will also play a certain role in reasonable classification.

The geometric shape of the grinding head liner is different, and its service life and scrap rate are different. The most important factor affecting the service life of the grinding head lining plate and the scrap rate, the phoenix shape wears a reasonable geometric shape of the grinding head lining plate according to the actual situation of the mill, so as to improve the life of the grinding head lining plate of the mill and reduce the its scrap rate, thereby increasing the mill run rate, reducing metal consumption and production costs.